The DISC Drill

Here's some pictures of the DISC drill at WAIS.

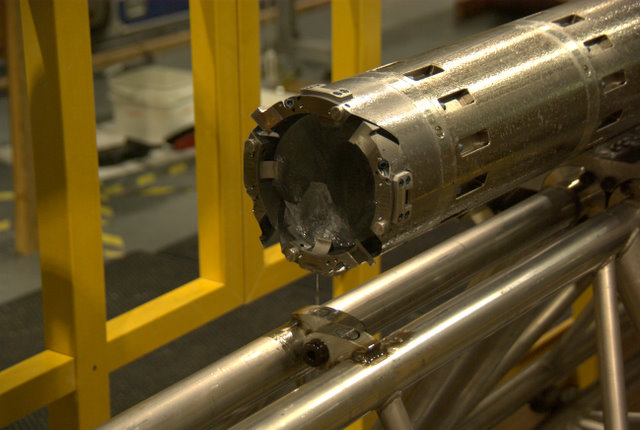

Here's the cutter head of the drill. The blades are at about the

2:00, 5:00,

8:00, and 11:00 positions. The core dogs, which are one way cams

that grab

the ice core and break it off for transport to the surface are at 1:00,

4:00,

7:00 and 10:00 positions.

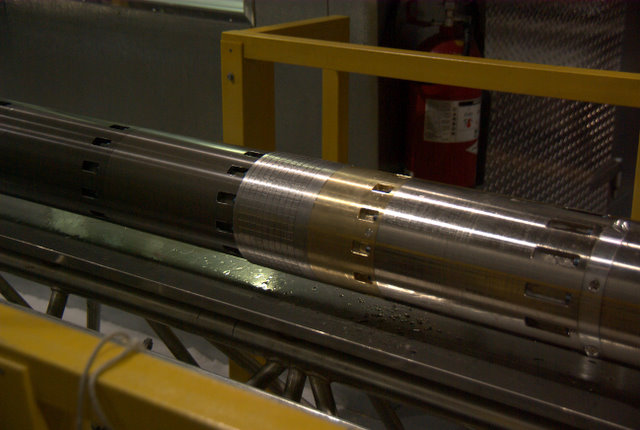

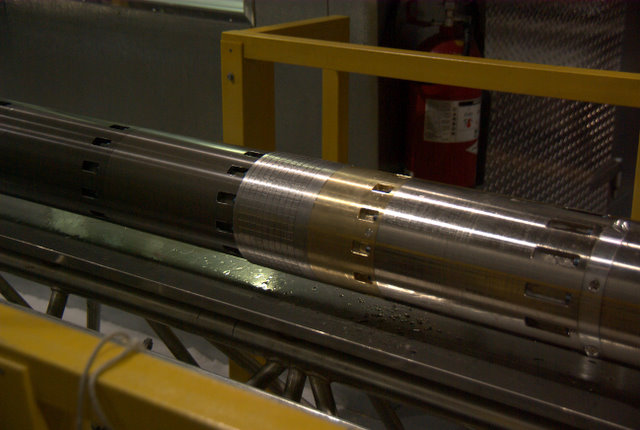

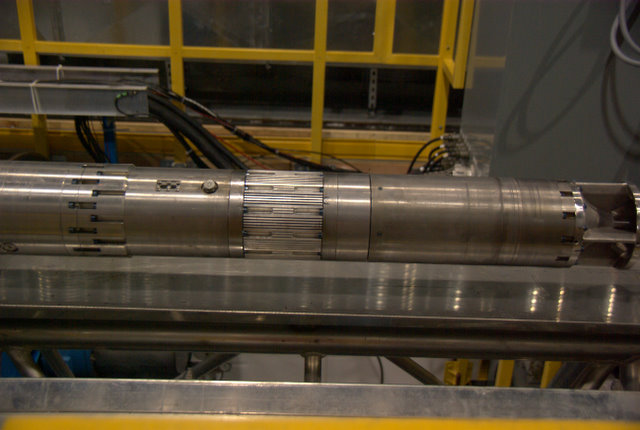

New for this year, is the thin kerf cutter barrel. It goes from

the cutter head

on the right to the brass band on the left, below the crane hook and

between

the two large windows on the control room. The thin kerf cutter

barrel

produces fewer ice chips, allowing longer ice cores to be cut before the

screen barrel is full.

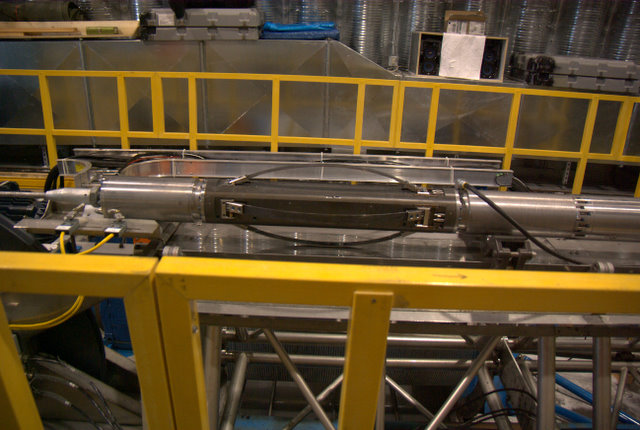

Here's the joint which separates the cutter barrel on the right from the

darker screen barrel on the left.

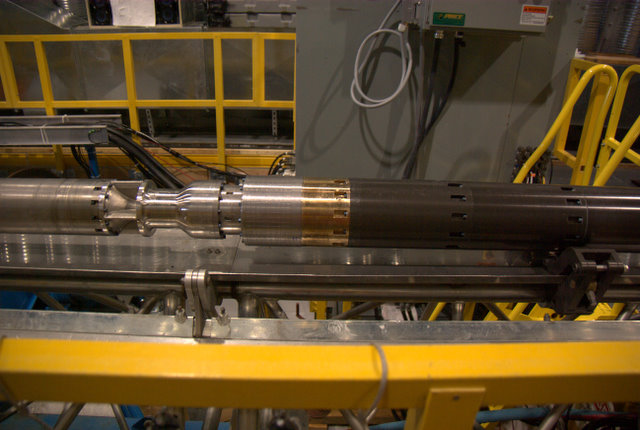

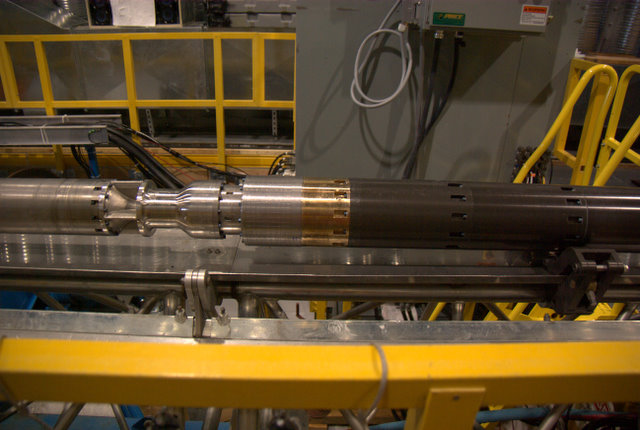

The screen barrel is the longest portion of the drill, and is not fully

pictured

in these shots. However, you get the idea; once you've seen one

screen

barrel portion, you've seen them all. This brass joint is the top

of the screen

barrel on the right, and the pump on the left. The pump

circulates the drilling

fluid with the ice chips from the cutter, over the ice core being cut,

up into

the cutter barrel screen barrels. Every time the drill

comes

to the surface with

another ice core, both the cutter barrel and screen barrel sections are

detached.

The cutter barrel then has the ice core removed. The screen

barrel section is

exchanged with another clean screen barrel section. The barrels

are then

reconnected and the drill is sent down again. The screen barrel

full of ice chips

is then cleaned.

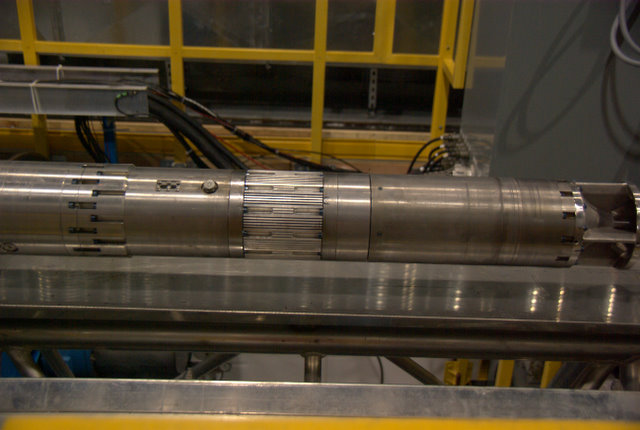

This is the motor section. It starts at the top end of the pump,

which is the

open area on the right. and ends with the blue screws on the

left. There are

two motors in this section. One for the cutter, and the other for

the pump.

The center ribbed portion is a heat sink to transfer heat away from the

motors.

To the left is the instrument section.

This is the instrument section. Not much to look at from the

outside, it

holds the brains and electronics of the drill. It is a sealed,

surface pressure,

container. It holds two computers, fiber optic modules, numerous

power supplies,

sensor electronics, power modules to drive the motors, a navigation

module, lots

of wires, and a gerbil inside to keep it all running.

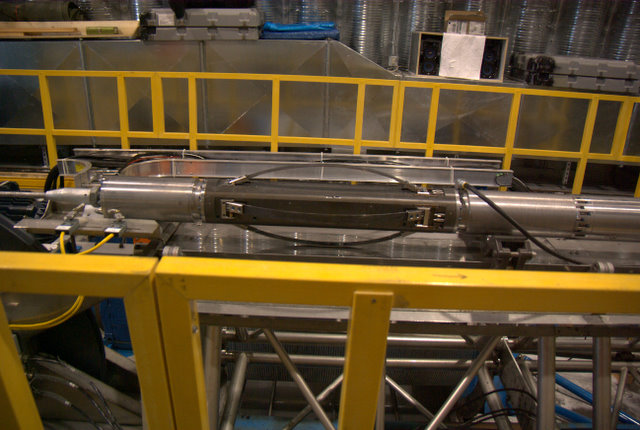

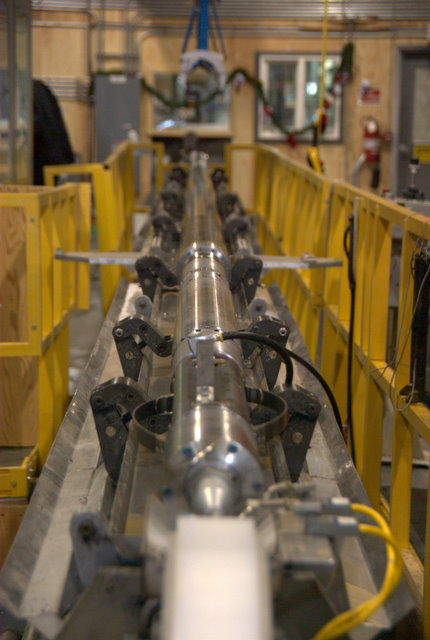

The top section is the anti-torque section. The four springs keep

the top of

the drill from spinning, and provide the reaction force for the cutters

to

operate. There are slip ring assemblies in this anti-torque

section which

allow the electrical and fiber optic portions of the cable to rotate

completely

independently from the drill.

This is the Farmor connector through which all the load of the drill is

smoothly transferred to the cable. The circular piece to the

right of the

large nut rotates with the cable, and the rest of the drill does what

it wants.

A view of the drill from the top.

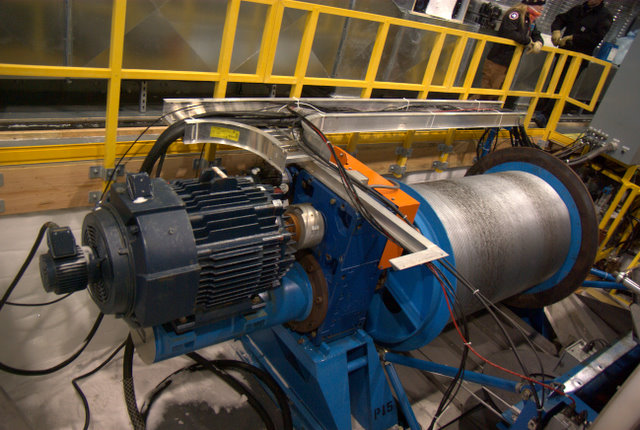

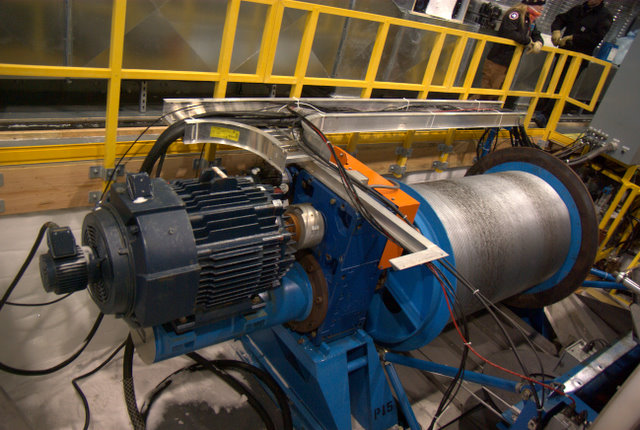

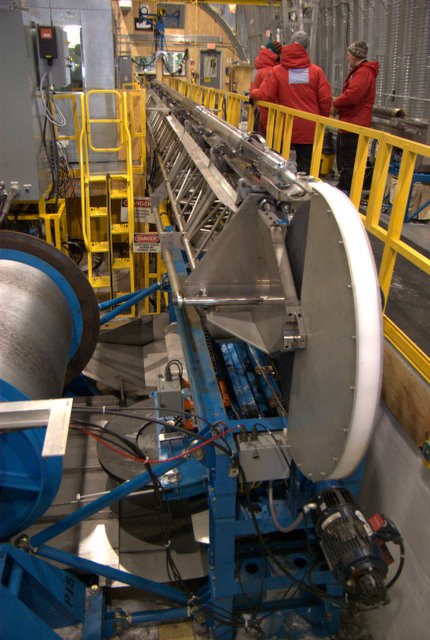

A view of the "winch pit." The large motor on the left is the 150

hp "trip"

motor. It pulls and lowers the drill and cable at relatively

rapid rates.

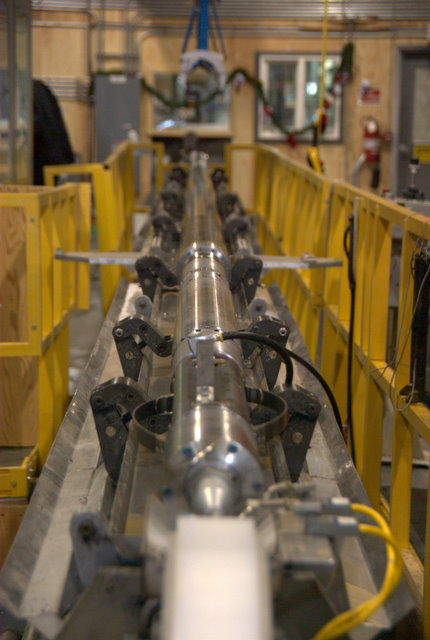

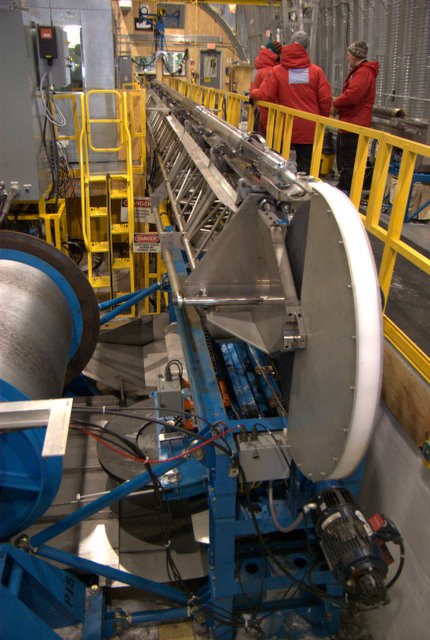

A view of the level wind assembly, and the top the tower,

when in the horizontal position. The motor in the lower

right runs the level wind via a long lead screw. The level

wind keeps the drill cable neatly wound on the winch.

The winch control cabinet is on the left, with cables coming out of it

on the

bottom and back. The control room is in the center. The

control cabinet

houses drive controls for the large motors which run the winch.

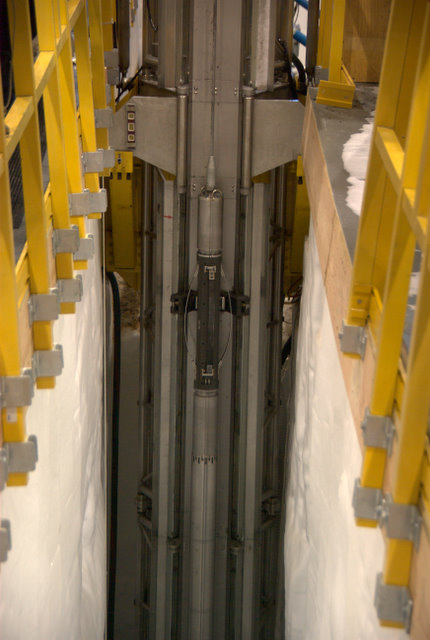

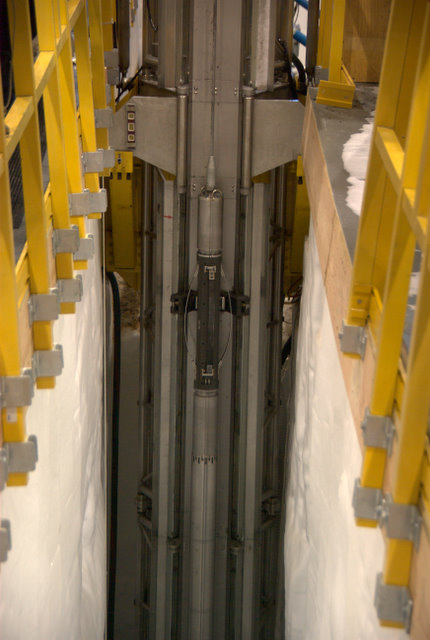

The drill being lowered into the bore hole. The tower

has been tilted vertical into the "slot", a narrow pit

approximately 30 feet deep and 5 feet wide that

provides the room for the tower to swing.

The top of the bore hole casing as the drill is being

lowered. There's tubes for drilling fluid, and drip

pans to funnel the drilling fluid back into the hole.

The white circle behind the drill is the bore hole cover

which is closed as soon as the drill is in the hole to

prevent something from accidentally dropping in the hole.

There's a slot in the cover to allow the cable to pass.

The yellow wire is a switch detector for the cover. This

picture was taken from some 40 or 50 feet away with a

flash as there's not good lighting at the bottom of the slot.

When the drill is at the bottom drilling, you can feel the vibrations

from the

cutting coming all the way up the cable. A multi-million dollar

version of two

tin cans and a string making a phone.

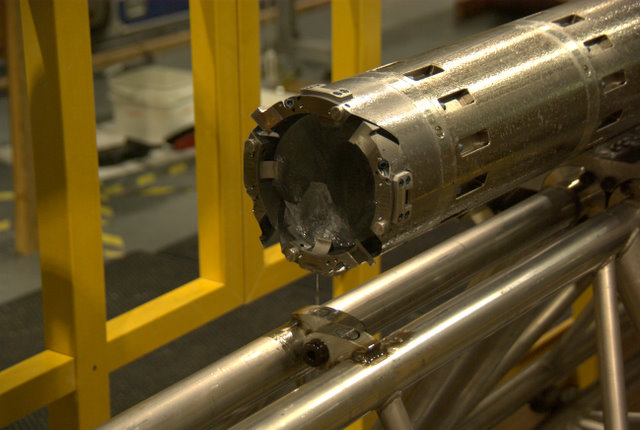

Here's an ice core at the surface, about to be removed. Drilling

fluid is

running out the end of the drill.

An ice core just delivered to the ice core handlers.

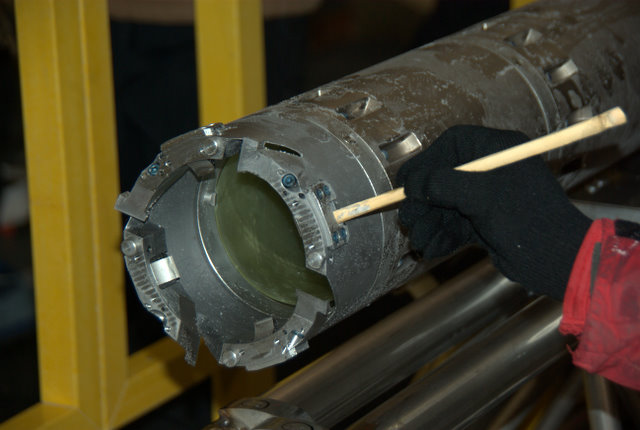

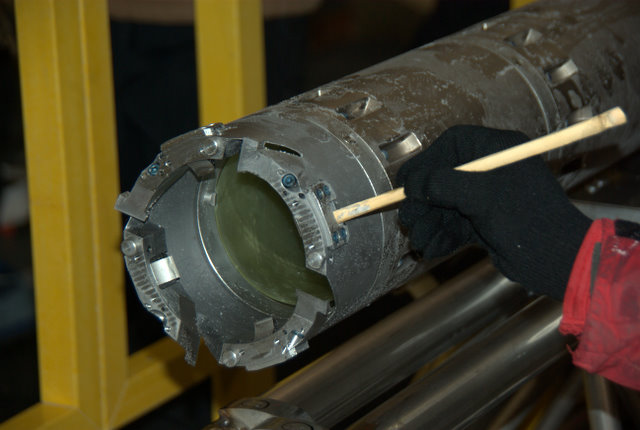

Using a piece of bamboo to clear ice chips from one of the core

dogs. If we

don't clean the ice from the drill head, a core dog could jam with ice

and

really chew up an ice core. Likewise, ice is cleared from the

cutter bits.