First Core of 2009/2010 Season!

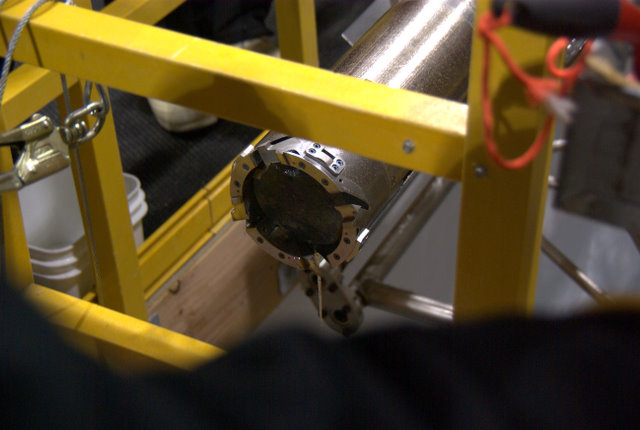

Near all hands are on deck as the first core of the season is brought

to the surface. The drill is raised on to the "tower" and is then

tilted

horizontal.

Here's the first ice core of the season! You can see the stream

of drilling fluid

running out the end of the drill, in about the 5 O'clock

position. This isn't the

greatest picture, as the crowd was pretty tight about the core, taking

many other

pictures.

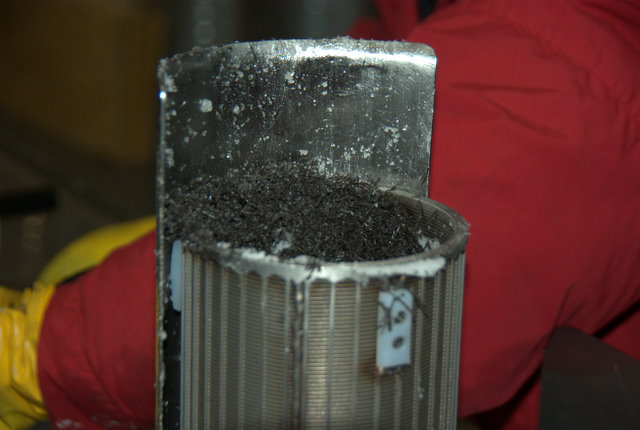

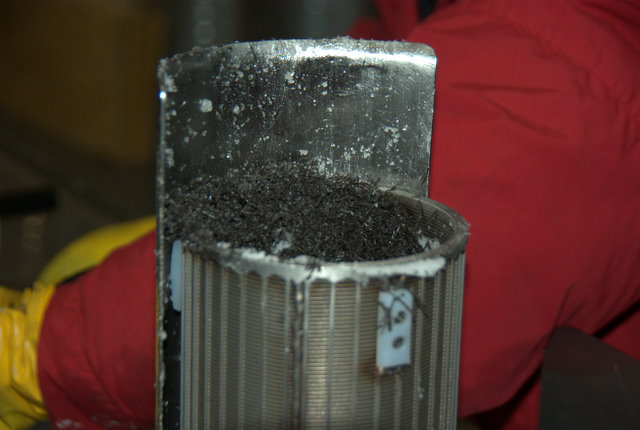

Here's why we're in Antarctica -- ICE CORE! Again, the view was

tight due to the

crowd. The extra black clumps on the core are from the new cable

"shedding" the

gap filler. They don't really contaminate the core, and are

removed. This is a

shot through a plastic window into the core handling room from the

drill "arch" room.

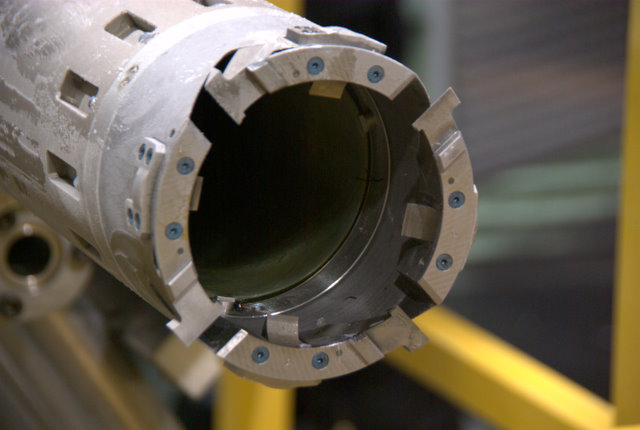

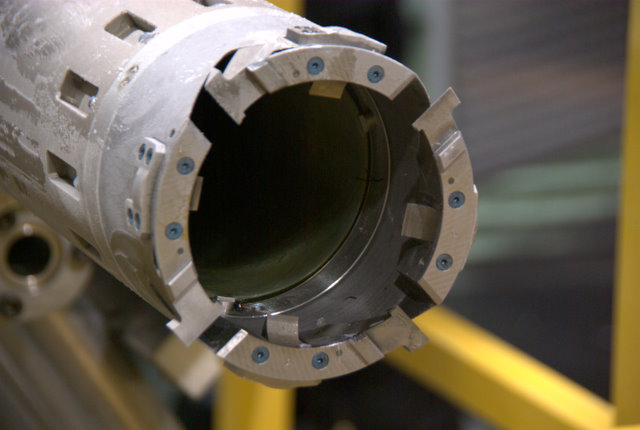

Here's the business end of the drill. The cutting blades are at

the 2, 4, 8, and 10

O'clock positions. The "core dogs", which are spring loaded

wedges that bite into the

ice core, are at the 12:30, 3:30, 6:30, and 9:30 positions. The

greenish fiberglass tube

into which the ice core passes is visible a few inches into the

barrel. There is a hollow

space between the outside of the fiberglass tube and the inside of the

stainless barrel

where the ice chips pass around the ice core and into the screen

section of the drill.

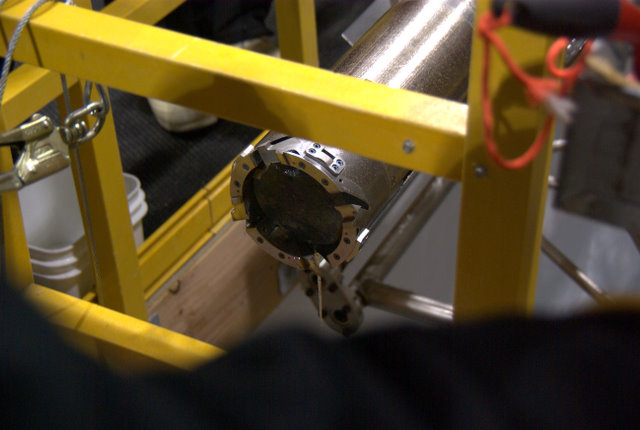

The gap filler from the new cable is choking the screen sections.

Fortunately, we

are only filling the screen sections with ice chips now.

Here's a view of the tower tilting as the drill is lowered to fetch

the second core of the season. You can see into the slot, and see

the access ladder we use to access the slot. A complete safety

harness system is used for all personnel access into the slot. If

you

look closely, you can see the core portion of the drill is very cold

from

the -25 C temperature in the bore hole and frosty from the relative

humidity in the arch. The portion of the drill that is not frosty

is the

screen section, which there are two of. We clean one as the

other

is being used, so the clean one "warms" to the -10 C in the arch and is

no longer so frosty.

The top of the bore hole. The cable that lowers the drill

into the hole is visible. The bottom of the slot has drip pans

which collect drilling fluid that drops off the drill as it is

rotated horizontal. A blue and red striped tube is used for

adding new fluid into the bore hole. The yellow wire is simply

a detector for the bore hole cover. The cover is white plastic

and edge-on right above the bore hole casing. The black is all

gap filler from the cable.

A view of the top of the tower. The encased pulley at the

top of the tower is called the crown sheave. The control

station is on the right, with the windows. It's heated.

Sometimes low tech works great with high tech equipment.

Here's (from bottom left) Lou, Jay, and Rob. Josh is on the right.

All are wearing protective yellow gloves and using scotch bright

pads to abrade the gap filler off the cable as it passes by.